By Tessa R. Salazar

Electric vehicle (EV) sales in the Philippines are projected to increase by 30% between 2024 and 2032. Thus, it has become ever more important to address a persistent challenge in this growing industry.

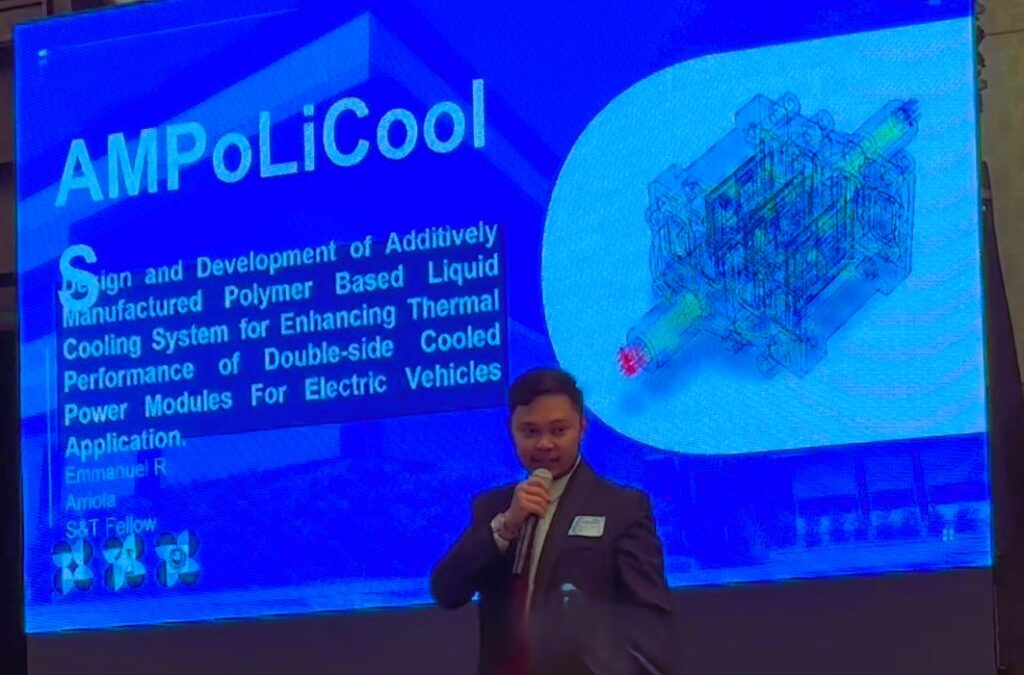

Engineer Emmanuel Arriola, a Department of Science and Technology (DOST) S&T Fellow, has presented a solution to the “thermal bottleneck” in EVs. He detailed his project during the 4th DOST S&T Fellows Convention at the Hilton Manila in Pasay City last Aug. 18. The convention highlighted innovations aimed at bringing science to local industries and communities.

Arriola’s work is one of 49 projects led by S&T Fellows, with over ₱700 million in total funding. As of August 2025, 58 S&T Fellows are embedded in various DOST agencies, helping shape the department’s research and development landscape.

DOST Secretary Renato U. Solidum Jr said: “S&T Fellows—composed of researchers, scientists, and engineers—are vital in strengthening DOST’s R&D capacity.”

Arriola’s project, AMPoLiCools (Additively Manufactured Polymer-Based Liquid Cooling System), is a novel cooling system designed to address overheating in EV power modules.

In EVs, power modules like traction inverters are crucial. They convert DC power from the batteries into AC power for the electric motors.

Asked if overheating power modules is an issue even among leading sophisticated EVs, Arriola said: “Yes, it is an issue that all EV manufacturers face because almost all commercially available EVs need power modules for their inverters because the motors they use are often AC motors due to their efficiency compared to DC motors. This means that finding a way to solve or at the very least, mitigate the overheating problems would be beneficial to all EV manufacturers and of course, to the consumers.”

Overheating power modules has two negative effects, Arriola explained: It reduces efficiency and mileage, or it shortens the EV’s lifespan. Lower efficiency means greater power loss. “The EV extracts less power from the battery, resulting in less mileage. And on the other end, for those who get higher ranges but experience overheating or thermal cycling, their EV’s life spans are shorter.”

This overheating issue is a key obstacle preventing EVs from fully delivering on their promise of efficiency, sustainability, and extended range.

Current status of AMPoLiCools

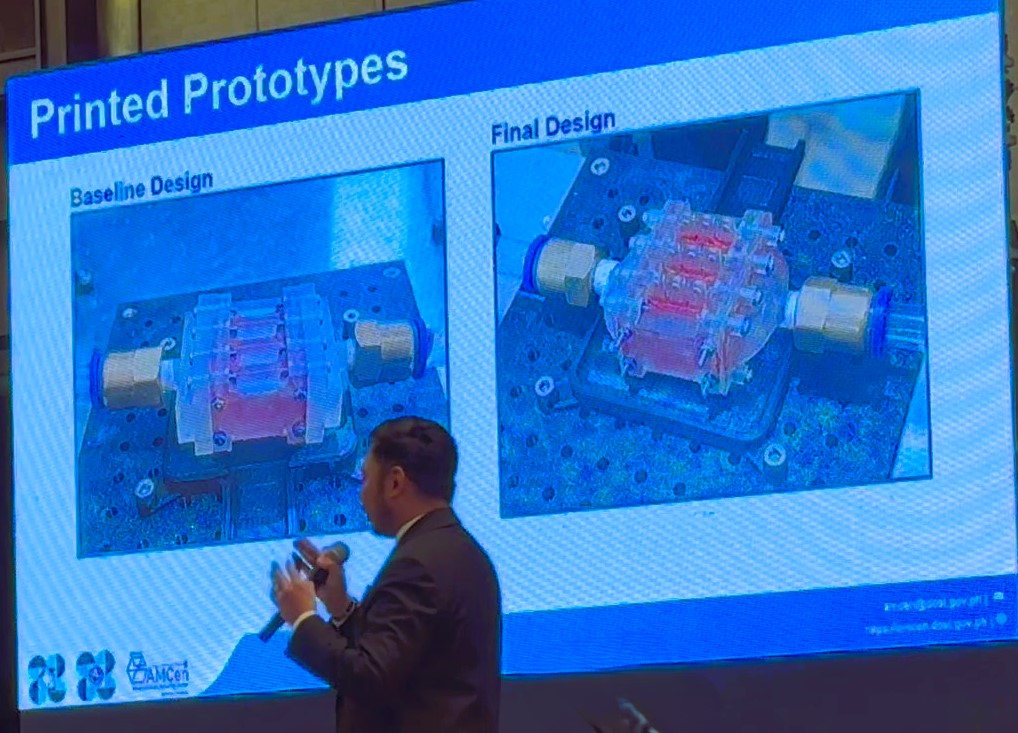

According to Arriola, the design and simulation stages are complete. Manufactured prototypes were sent to a US-based collaborator, Virginia Tech, where testing has finished. The team is now processing the experimental data to compare it with the simulation results.

“Virginia Tech is our collaborator in the United States. We’re not limiting this to EV manufacturers. The AMPoliCoolS technology can also benefit semiconductor manufacturers, since they also manufacture power inverters,” Arriola stressed.

Will AMPoLiCools solve the so-called “thermal runaway” that lead to the notorious EV fires?

Arriola explained: “The battery packs in an EV are usually composed of many cells that are connected together. When one cell overheats due to reasons such as mechanical damage, overcharging, or even a short circuit, a chain reaction called a thermal runaway may occur. The focus of our project is cooling power modules and not the battery pack itself. Taking this into consideration, we may need to investigate further how the process, techniques, and features we used in this project can be applied to these battery packs and to see if it can actually help mitigate the thermal runaway issues.”

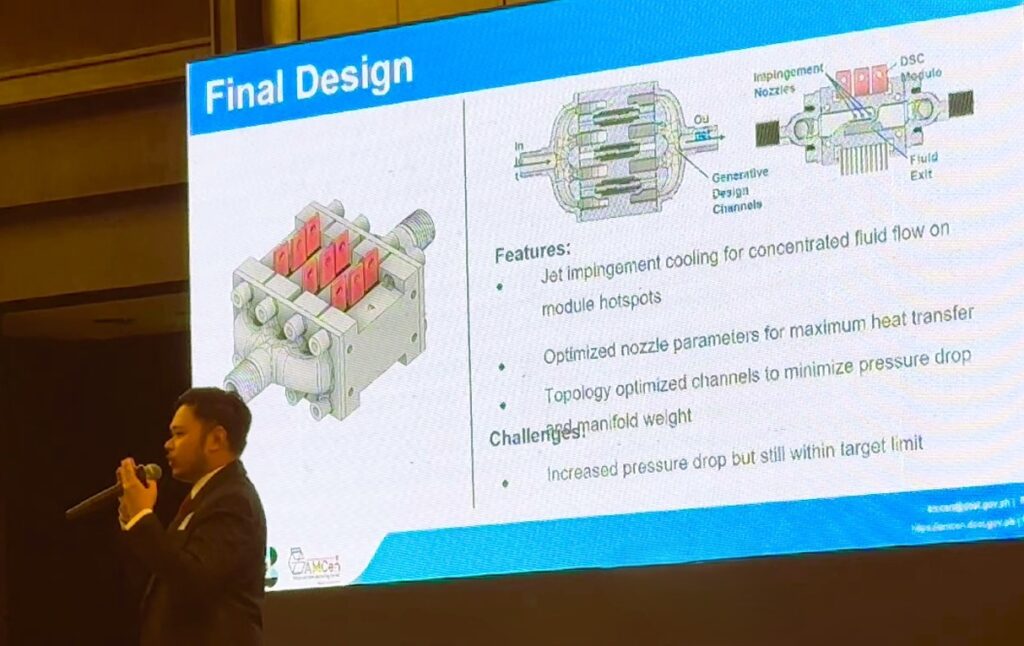

He further pointed out that most current EV cooling systems use liquid, but not in direct contact with the power modules themselves.

“In most cooling systems, there are cooling plates that are made of materials with high thermal conductivity (such as aluminum), which can easily transfer heat and that are in contact with the power module’s surface. The liquid flows within the channels of the cooling plate to absorb the heat. In the case of AMPoliCoolS, there’s no more cooling plates so the transfer of heat becomes more efficient. There’s direct contact between the surfaces of the power module and liquid,” said Arriola.

Is this system compatible with specific vehicles, including e-trikes?

“It’s not just the current design, but the concept and process themselves are the outputs of the AMPoliCoolS project. That means, the AMPoliCoolS concept is not tied down to the current design. It can be modified to accommodate other power module layouts. It can also be scaled down for lower power density applications, including e-trikes,” Arriola asserted.

Banner photo shows Arriola presenting his project during the 4th DOST S&T Fellows Convention