By Tessa R. Salazar

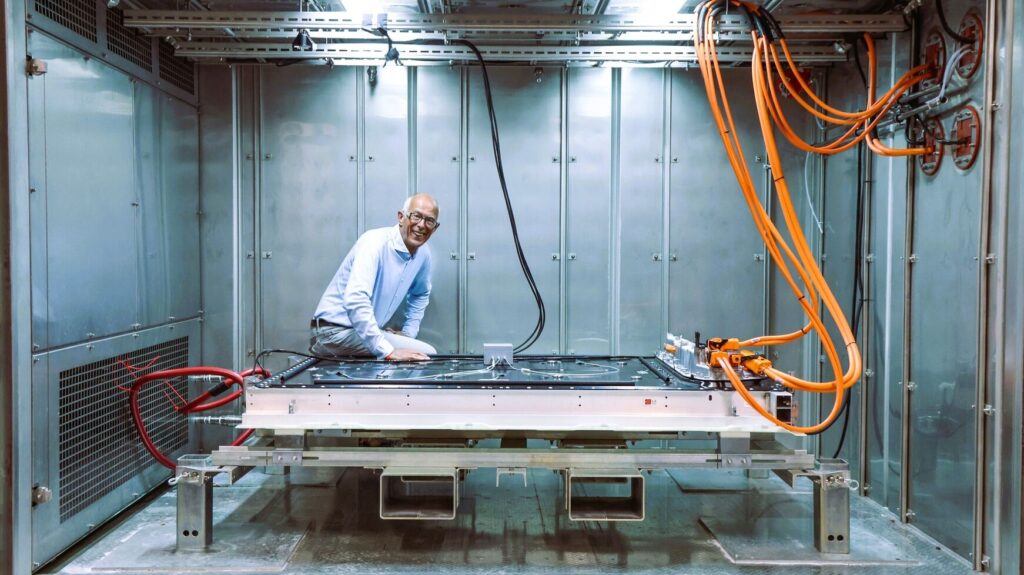

Porsche is setting high safety and durability standards for its high-voltage electric vehicle (EV) batteries, aiming to match the lifespan of combustion engines—at least 15 years or 300,000 km. This rigorous approach is detailed in the company’s recent publication, “Cell research at Porsche: Durability by design.”

Extreme tests

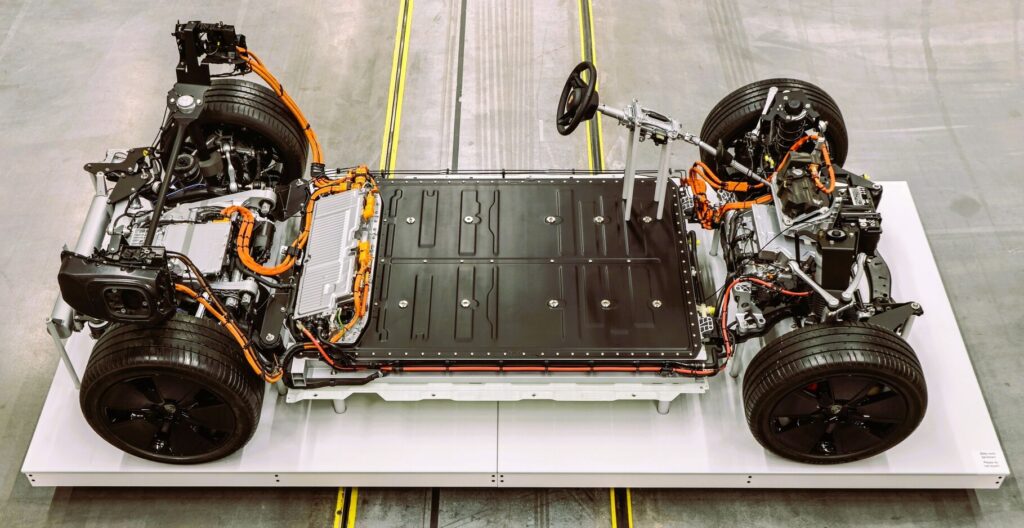

Porsche subjects its high-voltage batteries to an array of extreme testing protocols designed to be more rigorous than any vehicle’s lifetime.

Immersion test: The hermetically sealed battery housing is submerged about a meter deep in a flooded tank to ensure no water penetration, even after extended periods.

Corrosion test: The battery pack is exposed to various corrosive substances, particularly saltwater solutions of varying concentrations.

Crash safety: Occupant protection is the top design priority. For hybrid and battery-electric vehicles (BEVs), Porsche applies additional, strict internal requirements that simulate increased crash severity. Crash tests, such as a Macan undergoing a violent side impact against a solid pole, demonstrate virtually no deformation of the high-voltage battery due to the combination of structural optimization and comprehensive safety systems.

Component tests: Individual components, like battery modules, are tested under significantly higher loads than they would experience in a full-vehicle crash, and they must not catch fire.

Porsche Cayenne and Macan safety system governor Simon Maurer explains the crash protection strategy:

“We place all high-voltage components in areas where there is minimal risk of damage. Additional sensors detect critical stresses very early. After crash detection, electric motors and auxiliary units are automatically disconnected from the high-voltage battery, and the remaining stored energy is discharged dynamically. This prevents electric shock.”

Durability, performance enhancements

Porsche’s developers are focused on achieving long battery life, a minimal CO₂ footprint, maximum safety, and paramount driving dynamics—all without compromising fast charging or optimal performance.

Recent battery improvements have yielded significant gains:

Discharge current: Increased from 860 to 1,100 amperes, enabling faster and more powerful acceleration;

Capacity and weight: Gross battery capacity increased from 93.4 to 105 kWh, yet the weight was reduced from 634 to 625 kg, further benefiting the car’s handling;

Charging time: Short charging breaks ultimately reduce total travel time.

‘Influencing’ battery aging

The aging process of a lithium-ion battery is inevitable, but it can be influenced.

Initial drop compensation: Lithium-ion cells typically lose up to 5% of capacity in the first two to 12 months (the “initial drop”). Porsche accounts for this by ensuring newly produced batteries have an initial energy content that already compensates for this reduction. This engineering strategy results in the battery’s effective state of health (SoH) declining much more slowly over time.

Optimal conditions: Key parameters influencing aging include temperature, charge state, and charging current. Optimal conditions for long-term parking are temperatures below 30°C and a charge level below 90%.

Control technology: Porsche utilizes patented fast-charging technology in its electric sports cars for precise monitoring and control of these key parameters.

For more details, check Porsche’s online newsroom for the article “Cell research at Porsche: durability by design” or visit the direct link: https://newsroom.porsche.com/en/2025/innovation/porsche-e-performance-cell-research-drive-batteries-41288.html